|

Fifty years in the same business and the same location. We must be doing something right - but all the thanks has to go to our customers, our suppliers, and the quality-minded employees we have. It's a great time for Blue Ridge Fabricators!

0 Comments

We are pleased to announce the launch of our new website, now online. This effort was one of the priorities outlined by K. Julie Cox upon being installed as the president of the company earlier this year.

"I wanted to see something more interactive and responsive for our existing accounts, and a better tool for outreach to potential new customers. Our web hosting people didn't know our business, so we brought the redesign in-house to best accomplish our goals. We're very pleased with the result." The new website contains the fundamental information about the business, and features links to connect with us on various media platforms including Linkedin for more effective networking within the industries we serve. WWW.BLUERIDGEFAB.COM It's ironic that the whole time the third world was taking business from US manufacturers, we continued sending parts all over the globe. Now, when the world is paying attention to trade barriers and tariffs, we're busy repatriating the manufacture of parts that, for all intents and purposes, had been off-shored forever. How? We're not a multi-national conglomerate. We're not a huge corporation. We're a family run, woman owned small business - and we compete. It's simple. We maintain low overheads, operate without debt, focus on quality and efficiency, and charge a fair price for a quality product. Our customers are major manufacturers in every facet of equipment manufacturing. From small valves to huge earth moving equipment, we service those customers in ways that keep them internationally competitive. We also have exporters inserted into the supply chain that send our parts all over the world. If die cut parts play a part in your corporate economy and competing internationally is a challenge, contact us today to see how we can help. http://www.blueridgefab.com

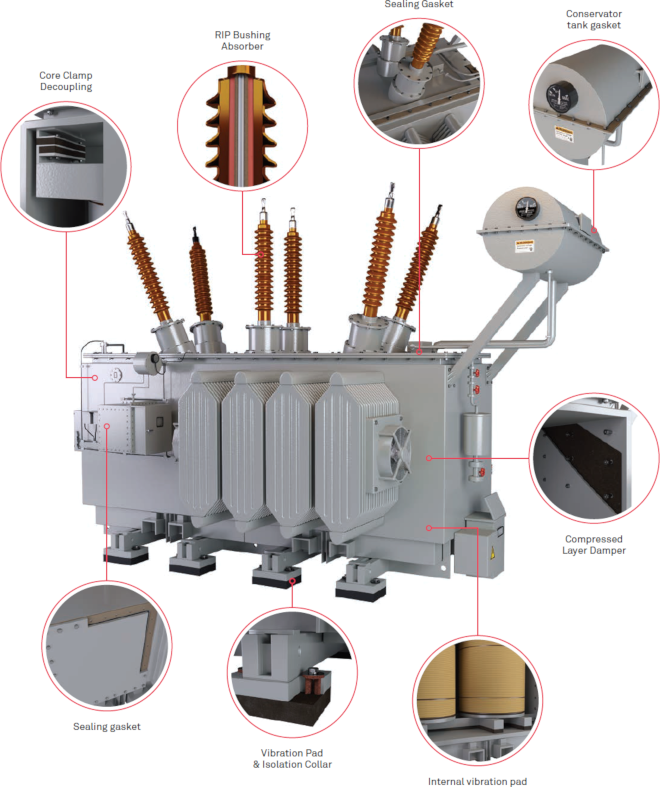

Transmission & Distribution Industry Power structures often endure harsh conditions and are therefore built to stand the test of time. Cork composites extend equipment lifetime in electrical power plants and distribution networks. Blue Ridge Fabricators has been manufacturing gaskets and supplying roll goods for the transformer industry over the last fifty years.

http://www.blueridgefab.com/

Cork based gasket materials have been in use since the pyramids were built. There's good reason cork remains in demand for use in wide ranging applications to this day. It works. Blue Ridge Fabricators cuts cork gasket materials for applications that include electric & electronic enclosures, natural gas & LPG, heavy duty diesel, industrial and small gasoline engines

From the original customer concept all the way through filling the supply chain pipeline, Blue Ridge Fabricators is a trusted resource for the natural gas equipment industry. Our material supplier partnerships, in-house technical expertise, and rapid prototyping get projects off to a quick start, and our production capacity delivers on time, every time. Natural gas and LPG? Yeah, we do that. Weekend pleasure boaters and tournament fishermen alike appreciate the reliability of the watercraft they depend on to get them safely back to the dock. Manufacturing parts for the boating industry has it's unique challenges, and all of them are considered when we engage our team. Everything we do is engineered for longevity and reliability. From engine gaskets to upholstery, you'd be surprised at all of the die cut parts on watercraft.

From the original customer concept all the way through filling the supply chain pipeline, Blue Ridge Fabricators is a trusted resource for the recreational marine industry. Our material supplier partnerships, in-house technical expertise, and rapid prototyping get projects off to a quick start, and our production capacity delivers on time, every time. Boats? Yeah, we do that. Whether you're tending to the yard on a Saturday afternoon or a landscape professional, everyone appreciates equipment that's dependable and built to last. It begins with high quality parts. Nothing is left to chance – not even the smallest of parts, like gaskets and heat shields.

From the original customer concept all the way through filling the supply chain pipeline, Blue Ridge Fabricators is a trusted resource for the landscape equipment industry. Our material supplier partnerships, in-house technical expertise, and rapid prototyping get projects off to a quick start, and our production capacity delivers on time, every time. Landscape equipment? Yeah, we do that. Without the power transmission industry our world would be at a standstill. Gearboxes and drive units are integral to every assembly line and conveyor application. These units must function flawlessly and almost endlessly. Gaskets and seals are critical elements in the unimpeded performance of power transmission equipment. Every gasket we fabricate is engineered for this same long term reliability.

From the original customer concept all the way through filling the supply chain pipeline, Blue Ridge Fabricators is a trusted resource for the power transmission industry. Our material supplier partnerships, in-house technical expertise, and rapid prototyping get projects off to a quick start, and our production capacity delivers on time, every time. Gearboxes? Yeah, we do that. Compressed air is used for much more than pumping up your tires or running pneumatic tools. Entire manufacturing plants are powered by air – making reliability of their production systems critical. This also makes the performance and service life of gaskets and seals incredibly important. Our generations long relationship with the compressor manufacturing industry is a testament to the quality of work and materials we supply.

From the original customer concept, all the way through filling the supply chain pipeline, Blue Ridge Fabricators is a trusted resource for the compressor industry. Our material supplier partnerships, in-house technical expertise, and rapid prototyping get projects off to a quick start, and our production capacity delivers on time, every time. Compressors? Oh Yeah, we do that. |

RSS Feed

RSS Feed